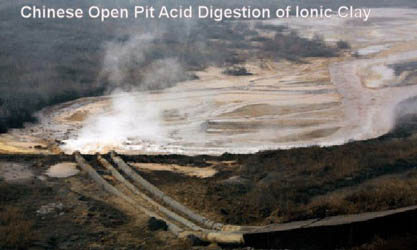

Ionic Clay Deposits extracted via Acid (Nitrate/Nitric) Wash

This method of spraying high-pressure Nitrate Acid streams at hillsides containing the ionic clays and soaking the clays with acids to extract the Rare earths [this could only be economic in China because of the enormous environmental damage it causes]. Acid run off is collected in sluices and further digested in separation facilities where the initial separations are fully refined in cascade chains of ‘Cameras’ or centrifuges as described above.

Chinese Open Pit Acid Digestion of Ionic Clays

The ionic clays deposits contain little Rare Earth Elements (by weight), but also have relatively minute amounts of Thorium or actinides. The ionic clays do contain a good distribution of Light and Heavy Rare Earth for what little there is.

In China, the only country where ionic clays are processed, collected Thorium extract streams are stockpiled for the stated purpose of energy production, most notably in a Thorium Molten Salt Reactor (TMSR) system being developed by the Chinese Academy of Science.

Phosphate Digestion for fertilizer facility Florida – Sarasota Magazine

Phosphate Liquors – A byproduct of mining, concentration, digestion and processing phosphate minerals for fertilizer is a waste ‘liquor’ by-product that contains the digested components of the phosphate mineral with the Phosphate removed. This is a potentially easy way to extract Thorium, Uranium and Rare Earths since the base process has already performed the difficult and resource intensive digestion step.

Hard Rock Mining – Another source of Thorium bearing minerals is from hard rock mining such as Iron mining. Often, the tailings from these mines contain minerals that are rich in cobalt, gold, rare earths and, of course, thorium, since thorium and rare earths are often commingled in the same mineralization. However, the concentrations of Thorium and Uranium is so low in most proposed hardrock mines that it is entirely uneconomic without extreme amounts of government subsidies.

Less Common or Proposed Thorium Sources:

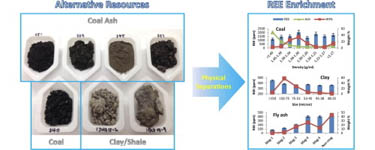

Extraction from Coal Ash – The Department of Energy of the United States has funded this work to extract Rare Earths as well as Uranium and Thorium from coal ash. The other coal related source is the overburden of the coal waste from mining, probably an even more concentrated source of RE Elements. While this source and separation has been demonstrated in a laboratory, it has not been proven economic at any level.

Coal Ash, Long Shot Source of Critical Materials

Recycling of Thoriated Components – Due to the environmental challenges associated with recycling thorium bearing alloys and other items, the thorium oxide can be separated from the original source material but due to high costs this is not currently seen as a viable source for Thorium.

The Bonds of Thorium and other critical material alloys are too strong to economically recycle

References:

- Rare Earths Industry: Technological, Economic, and Environmental Implications edited by Ismar Borges De Lima, Walter Leal Filho

- http://www.fipr.state.fl.us/about-us/phosphate-primer/chemical-processing-of-phosphate/

- https://www.netl.doe.gov/coal/rare-earth-elements